Altor Safety LLC Receives $800,000 New York State Grant For Upstart Company

$4.9 Million in Incentives Awarded to Manufacturers Across the State Will Provide Faster and More Secure Access to Life-Saving Medical Products

By Tina Traster

The coronavirus pandemic has torn apart many things, but it has also made for new and innovative alignments.

In April, Rochelle and Russell Fawkes, and Jonathan Scott – long-time friends and Rockland entrepreneurs – fused the strengths of their companies to form a new one, Altor Safety, LLC, a mask manufacturer.

Fawkes heads up the Congers-based company PowerPak Civil & Safety, a national distributor of safety and PPE equipment. Scott is CEO of Metro-Wall, a Valley Cottage-based manufacturer and installer of interior glass partitions.

Together, they’re part of a new army of manufacturing warriors that are fighting down the coronavirus.

For 25 years, PowerPak has distributed PPE to hospitals and utility companies. The company – besieged for product at the height of New York’s outbreak — understood the marketplace but did not have manufacturing ability. The supply chain was choked by demand. Rather than outsource, Fawkes teamed up with Scott, whose company brought manufacturing capabilities to the partnership.

“We didn’t have any control over supply or manufacturing,” said Lee Mornan, Business Development director for Altor. “We were getting requests we could not fill.”

For Scott, demand for glass office partitions initially slowed down during the early months of lockdown when workers were not going to work. He understood the pandemic called for new ways to think outside the box, pivot if possible, utilize capabilities in novel ways.

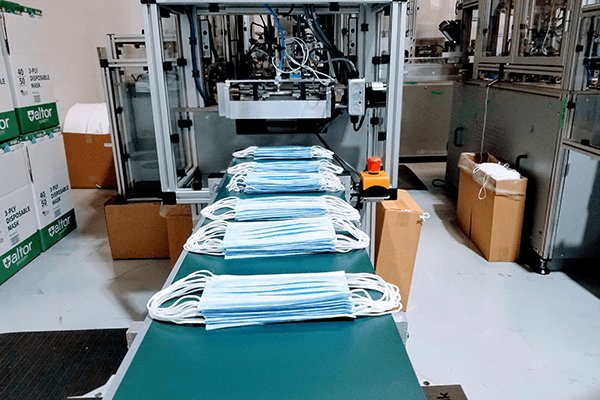

Today, Altor Safety is producing and distributing 3 million FDA-approved, 3-ply disposable face masks monthly. The company has invested more than $2.5 million to purchase machinery, equipment, and raw materials to manufacture and distribute product. MetroWall, which had occupied 8,000 square feet at 711 Executive Boulevard in Valley Cottage, has taken on an additional 20,000 square feet for the new venture.

In March, Governor Cuomo asked companies with New York-based operations to retool production lines to manufacture approved COVID-19 critical supplies, such as ventilators, test kits and PPE, including N95 respirators, surgical masks, gowns, and face shields.

“During the pandemic, the nation learned the hard lesson of not having adequate and readily available supplies made in the United States. As a result, we had to scramble for live-saving products that are mainly manufactured overseas,” Governor Cuomo said. “New York is building back better and our plan to move forward includes investing in the infrastructure that will keep us prepared and support local companies.”

Altor Safety is one of eight companies New York awarded $4 million to help make the products to combat the pandemic. The company received an $800,000 grant. In turn, Altor, which has hired nearly 40 people, and the New York Empire State Development Grant requires the company to steer at least 40 percent of its production of masks and other PPE products to New York.

Since April, Altor has scaled up from one automated mask-making machine to five, running both a morning and evening shift, to keep up with demand. Machines cost up to $400,000. The process begins with three rolls of fabric that are pleated into a mask, then cut and sent on a conveyor to “ear loop” stations where they welded in place before getting packaged.

Mask Wearing Will Become A Norm

“We foresee a changing world where masks will be worn for a long time to come,” said Mornan.

The company plans to up its production to 10 million masks a month.

“We are working on setting up distribution partners, building loyalty and trust – these are the challenges for a new business.” But Mornan said companies in the mask-making space have a distinct advantage: the crackdown on sub-par PPE being exported from overseas.

“There’s a glut of foreign product that’s sold at low prices,” he said. “We’re going to be wearing masks for a long time. People are going to be wanting a superior product. One that’s made in the USA.”

While New York currently has some of the lowest transmission rates in the United States, preparing for a second wave is vital to protecting essential healthcare workers and the public.

“These grant funds will help alleviate product shortages due to supply chain issues that could lead to unfair pricing practices,” said Cuomo. “These companies will also increase the State’s manufacturing capacity while creating new jobs and market opportunities. To date, more than $16 million in grants have been awarded to 28 qualifying New York-based companies to retool their business lines and pivot to manufacturing vital supplies for ongoing response and recovery efforts.”